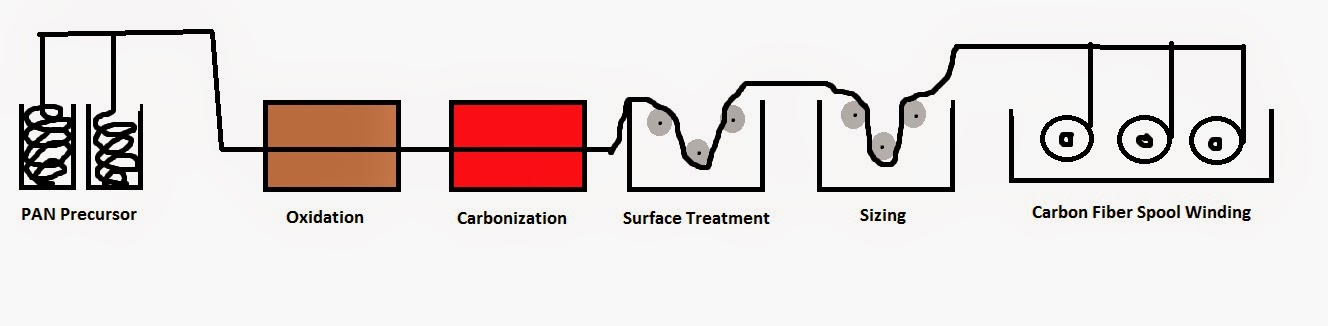

Carbon Fiber Production Process (PAN Based)

PAN Fibers (Polyacrylonitrile Fibers)

PAN Fibers started to producing in 1950s. It is a synthetic

semi crystalline organic resin which has a structure that ( C3H3N

). PAN can not melt under normal conditions and this property gives to

fiber flameproof characteristic. It is oxidized in air at 230°C and it is carbonized above 1000°C under normal conditions.

PAN is also a components repeat unit in some co-polymers

(eg. SAN, ABS). Main reason of that is acrylinite which in PAN. Textile

PAN is mixture of some co-polymers such as itaconic acid, acrylic acid,

methyl acrylate, meth-acrylic acid and vinyl acetate. These acids which

are in PAN structure effects reactivity of PAN.

PAN fibers can be made by wet, dry or melt-spinning process.

Wet process is the most important process and commonly there are two

solvents. These are DMF (Dimenthylformamide) and DMA

(Dimethylacetamide). PAN Fibers contains at least 85% acrylonitrile.

Stabilization of PAN Fibers

PAN is needed stabilization process before carbonization

because of it is a thermoplastic polymer. Stabilization process is also

known as oxidation. It is an important process that determines cost of

production and quality of product. Oxidation of PAN happens in

approximately at 300°C with the shrinkage level control. PAN Fibers changes their color on this process.

Best mechanical properties of stabilized PAN Fibers contain 10-14wt% Oxygen and has density of nearly 1.4g/cm³.

Carbonization of PAN-Ox (Oxidated PAN)

Carbonization of PAN is shorter process than oxidation. PANs temperature is changed rapidly to 3000°C. This process happens under N2 atmosphere. This condition is safe for environment.

In conclusion Oxidation and Carbonization are the most important parts

of to determination of characteristic of PAN based carbon fibers.

Graphitization of PAN fibers

Carbonized PAN fibers structures are made similar to graphite and

crystallography which include grain size and directions is arranged.

Most important effect of graphitization is decreasing fibers strength

but increasing density, thermal conductivity and Young's modulus.

Hiç yorum yok:

Yorum Gönder